Proflex Elite

Impermeable Acrylic Sports Surface for Tennis

Proflex is an impervious acrylic surface offering optimum cushioning.

There is a version of Proflex for each ITF Court Pace class. It is suitable for use in conventional and wheelchair tennis playing.

The system comprises a high quality 6mm* rubber mat which is bonded and coated using durable textured polymers to produce a superior cushioned tennis surface.

*Varying thicknesses of cushioning mat can be supplied on request.

As well as being extremely durable and resistant to wear, the cushioning effect will remain constant throughout seasonal temperature variations and over many years of use. Because the cushioning mat is prefabricated to a uniform thickness this will allow a true ball bounce on all areas of the court.

Other types of Proflex

ITF Pace Classifications

Normally, Proflex is available in versions that have ITF Pace Classifications of 2, 3 and 4. But, by varying the formulation of the components used in Proflex it is possible to produce surfaces with ITF Pace Classifications of 1(Slow) and 5(Fast) in addition.

Normally, Proflex is available in versions that have ITF Pace Classifications of 2, 3 and 4. But, by varying the formulation of the components used in Proflex it is possible to produce surfaces with ITF Pace Classifications of 1(Slow) and 5(Fast) in addition.

The environment

The materials used in these surfaces are environmentally friendly, using recycled rubber for the cushioning mat, together with solvent free adhesives and water based polymer coatings.

Colour Range

The standard range of colours comprises those shown here.

The standard range of colours comprises those shown here.

Please note that the colours are for illustration only and actual colours may differ considerably from those on the screen.

Any other choice of colour can be formulated on request.

Proflex in Action

The ABN AMRO World Tennis Tournament is, according to the organisers, among the eleven most prestigious tournaments on the ATP 500 tournament circuit, with annual participation from the best tennis players in the world and more than 100,000 visitors.

The courts for the competition have to have world class performance characteristics acceptable to the ATP and be installed on a temporary basis. The venue, Ahoy in Rotterdam, is used for a variety of expos, competitions, concerts and large scale events.

Proflex Meets the Tough Competition Requirements

A total of 7 courts (that is an area of over 5000m2) were installed at the venue. The surface was laid on a temporary structure fabricated from wooden boards.

The competition was held in February of 2014.

- Two courts were utilised in the wheelchair tennis tournament.

- One court - the Show Court - was used for demonstrations, coaching and other entertainment.

- The Centre and Court 1 were used for the competition proper.

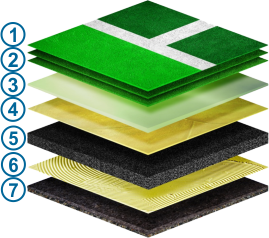

A sand-filled, coloured, single pack, water-based acrylic/polyurethane coating, providing texture and additional strength to the surface.

A sand-filled, coloured, single pack, water-based acrylic/polyurethane coating, providing texture and additional strength to the surface. A sand-filled, coloured, single pack, water-based acrylic/polyurethane coatings, providing texture and additional strength to the surface.

A sand-filled, coloured, single pack, water-based acrylic/polyurethane coatings, providing texture and additional strength to the surface. A self-levelling two-part polyurethane wear layer that strengthens the surface and provides area elasticity.

A self-levelling two-part polyurethane wear layer that strengthens the surface and provides area elasticity. A durable and flexible two-pack polyurethane coating, which fills the pores of the rubber shockpad providing excellent mechanical and chemical adhesion.

A durable and flexible two-pack polyurethane coating, which fills the pores of the rubber shockpad providing excellent mechanical and chemical adhesion. Pre-fabricated to the required thickness, the shockpad comprises recycled rubber particles bonded together with a polyurethane binder.

Pre-fabricated to the required thickness, the shockpad comprises recycled rubber particles bonded together with a polyurethane binder. A two-pack polyurethane adhesive is coated over the entire surface of the substrate to provide total bonding of the rubber shockpad.

A two-pack polyurethane adhesive is coated over the entire surface of the substrate to provide total bonding of the rubber shockpad. Macadam or concrete. Generally built to a gradient of 1:100 to 1:150.

Macadam or concrete. Generally built to a gradient of 1:100 to 1:150.